Xingaonai

Xingaonai

In the fields of construction, road construction and concrete preparation, stone chips and artificial sand are often mentioned as common aggregate materials but are easily confused. Although both are derived from rock crushing, there are significant differences in their properties, production processes and application scenarios. So what is the difference between the two? Xingaonai Heavy Industry will explain in detail.

Stone chips: also known as screening chips or artificial sand, are the aggregates under the sieve with 2.36mm or 4.75mm sieve holes in the process of processing crushed stone in the quarry. Its particle size range is usually 0-5mm or 2-10mm. As a by-product of crushed stone production, it has not been finely screened and shaped, and the particle properties are greatly affected by the original stone crushing process.

Mechanical sand: refers to the process of processing rocks into particles with a particle size of less than 4.75mm through mechanical crushing, screening and other processes. Its production process strictly controls the particle size distribution, and the particle shape and grading can be adjusted according to demand. Mechanized sand is usually made of mine tailings, industrial waste slag, etc., and is made after soil removal. It is a high-quality aggregate that is artificially controlled.

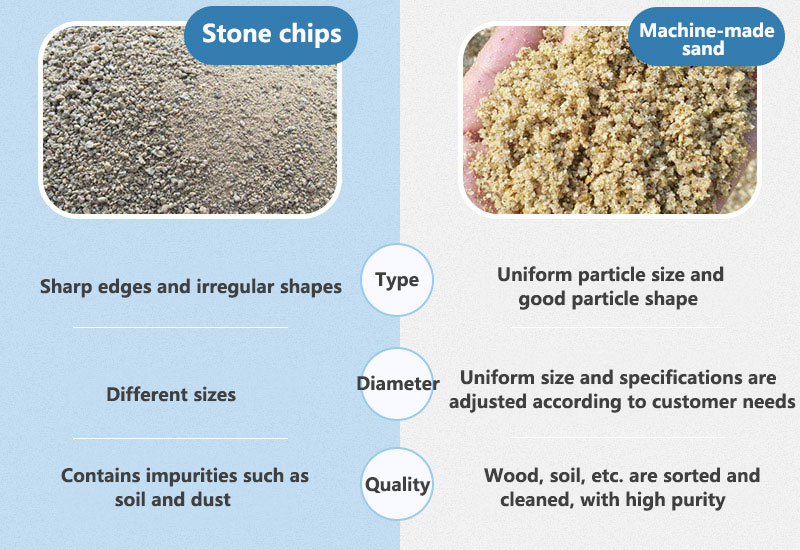

1. Difference in particle shape

Machine-made sand undergoes fine crushing, sand making and screening processes, and its particle shape is mostly regular cubes; while stone chips have not undergone special processing, and the particle shape is irregular and angular.

2. Difference in particle size

The particle size of stone chips varies, usually mixed between 2.36mm and 4.75mm, and the particle size distribution is extremely unreasonable. In contrast, machine-made sand is processed into different particle sizes according to specific process requirements, and the particles are uniform.

3. Quality comparison

The stone chips with a particle size of less than 0.16mm have a higher content of stone powder and mud, and the surface is rougher than machine-made sand. The machine-made sand produced by a reasonable process has a stone powder content and mud content that meet the standards for construction sand, and the stone has a higher compressive strength.

Stone chips need to undergo specific process treatment before they can be used as machine-made sand, and stone materials also need to go through production processes such as feeding, crushing, sand making, and screening before becoming machine-made sand. The following are the specific steps of the sand production process:

Introduction to the production process of stone chip sand making

Shaping: The collected stone chips will be sent to the stone shaping machine (such as impact sand making machine or heavy hammer crusher) for in-depth processing to improve the excessive angular and irregular shapes of the stone particles;

Powder selection: In the dry sand making process, the powder selection machine is used to recover 0.075 mm stone powder from the stone chips, thereby reducing the stone powder content in the finished product, and then screening to distinguish different finished product specifications;

Sand washing: In the wet sand making process, the 3-6 mm and 0.075-3 mm finished products are first screened, and then the impurities in the finished products are removed by water through the sand washing machine and the mud content is reduced.

Introduction to the production process of machine-made sand

Feeding: The mined stone is usually transported to the silo and then falls into the vibrating feeder, or is directly placed on the feeder by the excavator. After simple screening, the stones of different sizes are classified and then sent to the coarse crusher for further processing.

Crushing: The primary crusher, i.e. the jaw crusher, first performs preliminary crushing on the stone, reducing its particle size to 500-800mm. Next, the secondary crusher (impact crusher or cone crusher) further processes the stone into finer particles of 5-50mm.

Sand making: The stone after secondary crushing is processed by sand making equipment (impact sand making machine, fine crusher, etc.) to further reduce the particle size to less than 50mm, and finally form machine-made sand with a particle size of less than 4.75mm. Throughout the process, the role of the vibrating screen is to ensure that the finished product particle size meets strict standards.

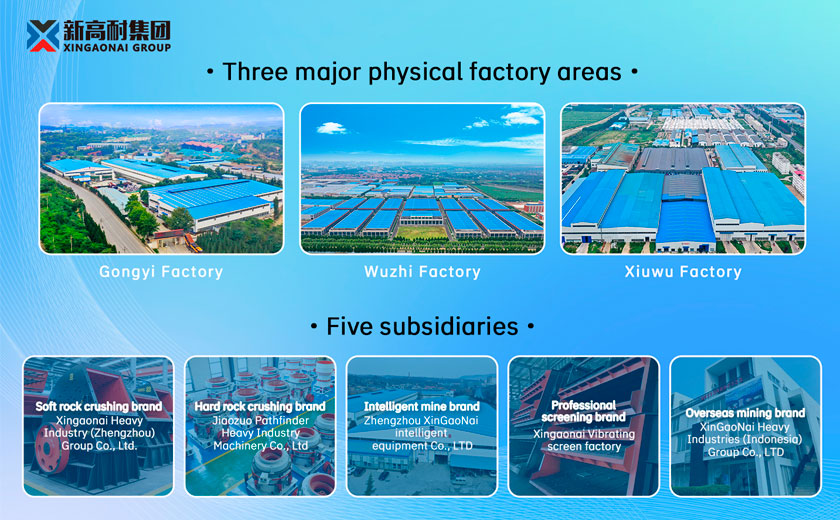

Impact sand making machine, jaw crusher, impact crusher, cone crusher, etc. are indispensable equipment for stone chip sand making and machine-made sand production. Their technology and quality are enough to affect the revenue of the entire line, so it is necessary to focus on the choice of manufacturers. Here we recommend Xingaonai Heavy Industry for the following reasons:

We have the advantage of advanced technology, and our professional R&D team continues to explore and innovate. We combine the introduced advanced technologies at home and abroad, as well as high-end equipment such as vertical CNC gunnery machines, and are committed to meeting the diversified needs of users, increasing revenue and reducing consumption.

The quality of the equipment is reliable. From the fuselage to every vulnerable part, it is carefully cast with high-quality alloy materials. Even the manufacturing of parts and components adheres to the concept of excellence, so as to minimize the failure rate and ensure the stable operation of the equipment.

Our services are even more complete, covering pre-services such as equipment recommendation, process design, process planning, mid-term support such as accompanying installation, commissioning and operation training, as well as post-guarantee such as regular return visits, long-term quality assurance, and providing original accessories, so that every user can put into production with confidence without worries.

Superior: Advantages and maintenance of Xingaonai impact crusher

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap