Xingaonai

Xingaonai

Mining mixing barrels, also known as mining mixing drums, are indispensable mechanical equipment in the mineral processing process. They are mainly used for slurry mixing before flotation operations to ensure that the reagents and mineral particles are fully mixed, creating favorable conditions for subsequent flotation separation. With the expansion of the scale of mining resource development and the application of intelligent technology, mining mixing barrels have been continuously innovated in terms of structural optimization and efficiency improvement, becoming an indispensable link in modern mining production.

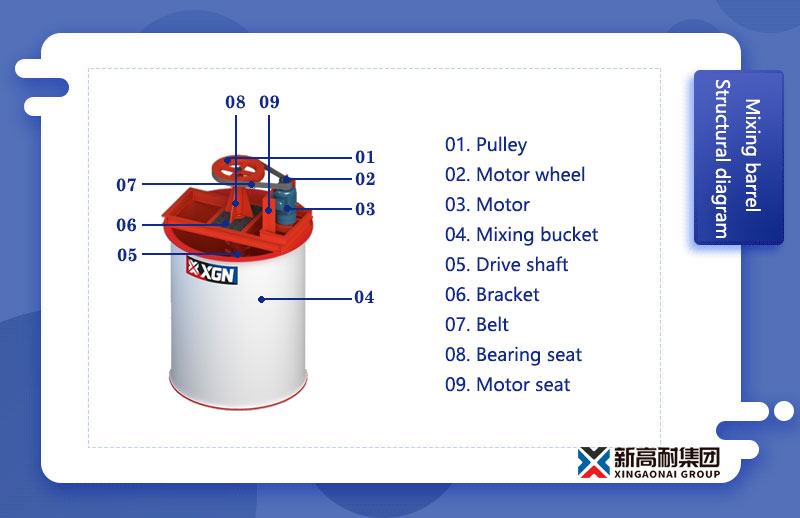

Agitator system: The core component of the mixing barrel is the agitator, which is usually composed of an impeller and a transmission device. Common impeller types include straight-blade inclined impellers, spiral curved impellers, etc., which generate axial flow or radial flow through high-speed rotation to promote slurry circulation and achieve solid suspension and mixing.

Baffle: Installed vertically on the barrel wall, it converts the rotating flow into a vertical flip flow, eliminates vortices, and improves the utilization rate of the stirring power. The standard baffle is usually 4 pieces, with a width of 1/12 to 1/10 of the tank diameter to ensure uniform mixing.

Guide tube: The impeller is located in the tube, and the internal and external circulation is formed by negative pressure pump suction, but the distance from the bottom needs to be controlled to avoid sinking; the impeller is located in the lower part of the outer tube, and local circulation is formed through the circulation port, which is suitable for small and medium flow; the special structure, combined with the conical bottom and the distribution plate, realizes the "W" type large circulation, and enhances the solid suspension and mixing efficiency.

The motor drives the impeller to rotate at high speed, generating shear force and turbulent field, so that the slurry and reagent form multi-directional flow in the barrel. Mineral particles are evenly dispersed under the action of centrifugal force and axial flow to avoid agglomeration. At the same time, the reagent molecules are fully adsorbed on the surface of the mineral, providing the necessary conditions for flotation reaction.

Mining mixing barrels are widely used in the pre-flotation treatment of metal and non-metallic minerals. The specific functions include:

Reagent mixing: ensure uniform contact between reagent and slurry, improve reagent reaction efficiency, and avoid local concentration unevenness affecting the flotation effect.

Particle suspension: overcome the agglomeration of fine-grained minerals through stirring force, prevent sinking, and improve flotation recovery rate.

Process connection: As the front link of flotation equipment, it reduces the flotation machine's slurry adjustment energy consumption and optimizes the overall sorting efficiency.

Cooperation between flotation machine and flotation column: Good slurry adjustment effect can reduce the flotation machine's own slurry adjustment energy consumption and reduce the energy loss in the sorting process. For flotation columns, the high-quality mixing operation of the front mixing barrel can significantly improve the adhesion efficiency of bubbles and mineral particles and optimize the sorting index.

Demand for fine-grained mineral processing: In view of the characteristics of "poor, fine, and mixed" ores, the mixing barrel overcomes the agglomeration of fine-grained minerals through a high-intensity mixing flow field, ensures that the reagent fully reacts with the mineral surface, and improves the recovery rate.

Balance between energy consumption and efficiency: Efficient mixing design needs to strike a balance between solid suspension and energy consumption to avoid excessive mixing leading to reagent overflow or energy waste.

Compared with traditional mixing equipment, the advantages of Xingaonai high-efficiency mixing barrel are clearly visible:

Efficiency improvement: mixing time is shortened by 30%-50%, and production capacity is doubled;

Energy consumption reduction: frequency conversion technology reduces power consumption by 15%-25%;

Labor cost compression: automated control reduces manual intervention, and one-button start can complete the entire process of mixing and unloading;

Quality stability: uniformity error is controlled within ±1%, eliminating batch differences;

Environmental protection and safety: sealing design reduces dust/waste gas emissions, and intelligent early warning system prevents equipment failure.

As the "front hub" of mineral processing technology, the technological innovation of mining mixing barrels has always been closely related to resource development efficiency. From the refinement of mechanical structure to intelligent control, the development of mixing barrels will continue to promote the mining industry to move towards high efficiency, green and scale. In the future, with the integration of new materials and automation technology, its performance boundaries will continue to expand, providing more solid equipment support for the utilization of global mineral resources. If you want to know more about mixing barrels, you can consult customer service online or call +8617761642222. Xingaonai will arrange senior engineers to answer you as soon as possible!

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap