Xingaonai

Xingaonai

Spiral sand washing machine and spiral classifier are common models in mineral processing equipment. They are often confused because of their similar appearance. However, there are significant differences in design principles, functional applications, structural characteristics and processing effects between the two. This article will analyze the differences between the two from multiple dimensions to help users choose the right equipment according to actual needs.

Principle and composition structure of spiral sand washing machine

Principle: The blade is solid blade-shaped and the overall structure is compact. The equipment is arranged at an angle, and the spiral head is immersed in the sedimentation tank. Through continuous rotation, the sand and gravel are driven to interact with the water flow to achieve cleaning, desludging, dehydration and preliminary classification.

Composition: The sand washing machine is mainly composed of a tank body, a reducer, a motor, a solid spiral blade and a sealing transmission device, emphasizing sealing and cleaning efficiency.

Structure and function of spiral classifier

Principle: The blade is hollow and suspended, and the hollow design facilitates material flow. Using the principle of different specific gravity of solid particles and different settling speeds in liquid, fine particles are discharged through spiral stirring, and coarse particles are discharged after sedimentation, so as to achieve precise classification.

Composition: The classifier includes a transmission device, a spiral body, a trough body, a lifting mechanism, a bearing and a discharge valve. The structure focuses more on classification accuracy and material diversion control.

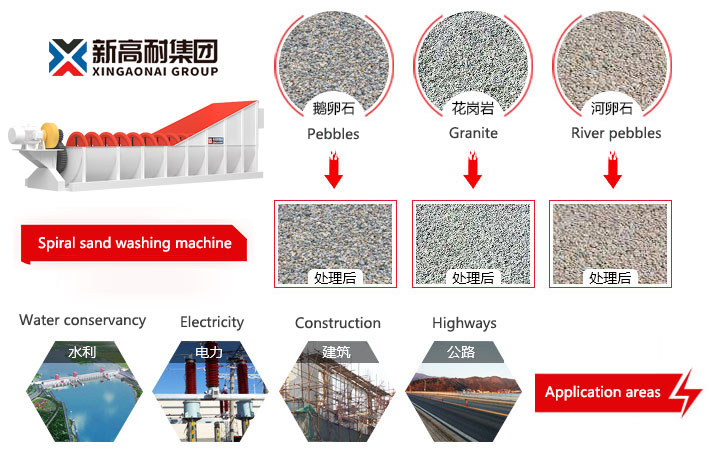

Spiral sand washing machine: Focuses on the cleaning and impurity removal of sand and gravel, and is suitable for the cleaning and purification of non-metallic minerals such as construction sand, road sand and gravel, and quartz sand. Its core function is to improve the cleanliness of sand and gravel, remove soil and dust, and meet the high standards of the building materials industry.

Spiral classifier: Widely used in ore dressing plants, metal ore processing, building materials sand making, environmental sludge treatment and other fields. Not only for ore sand classification, but also can form a closed-loop cycle with the ball mill to complete the pulp particle size classification, desludging and dehydration operations, and the function is more comprehensive.

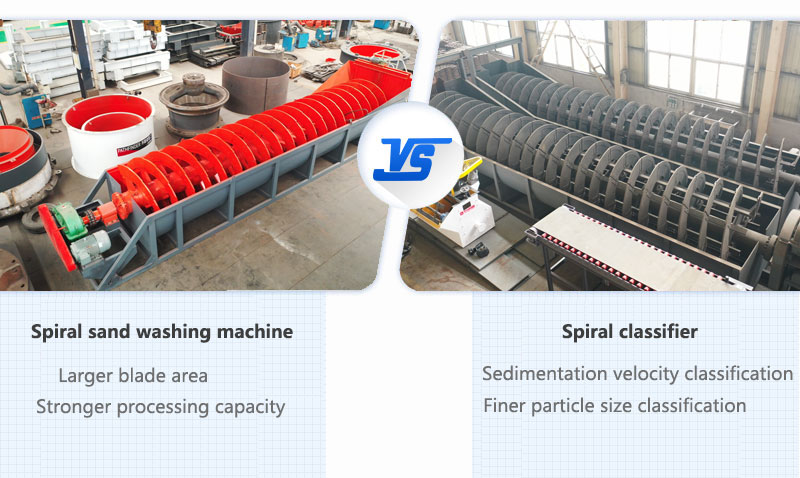

Spiral sand washing machine: The blade area is larger, the amount of material transported per unit time is higher, and the processing capacity is about 2-3 times that of the same size classifier, which is suitable for large-scale sand and gravel cleaning scenarios. Although the spiral sand washing machine has the function of classification, its main advantage lies in efficient desludging and dehydration, and the cleanliness of the sand and gravel after cleaning is higher.

Spiral classifier: Through the classification of sedimentation velocity, finer particle size classification can be achieved, which is suitable for the mineral processing process with strict requirements on particle size.

Spiral sand washing machine: low power consumption, fully enclosed transmission device reduces dust pollution, adjustable weir plate flexibly adjusts the classification effect, easy maintenance, suitable for continuous high-intensity operation.

Spiral classifier: wear-resistant materials are used to extend the life of the equipment, modular design is easy to maintain, and remote monitoring and multi-functional integration (such as classification + dehydration integration) are gradually realized under the trend of intelligence, which adapts to complex mineral processing processes.

Although the spiral sand washing machine and the spiral classifier are similar in appearance, the essential difference lies in "cleaning as the main" and "classification as the core". Only by understanding the technical differences between the two and combining them with actual production needs can the optimal equipment be selected to improve production efficiency and economic benefits. Before purchasing, it is necessary to clarify the material characteristics, processing scale and process requirements to avoid investment deviations due to confusion of equipment functions.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap