Xingaonai

Xingaonai

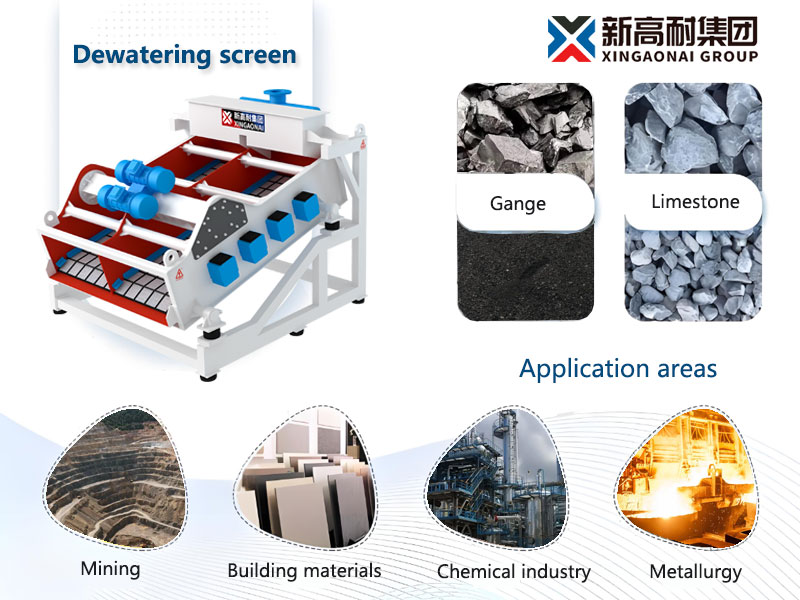

Dewatering screen is a solid-liquid separation equipment widely used in mining, construction, chemical industry and environmental protection. Its main function is to separate the water from water-containing solid particles through vibration to achieve the process requirements of dehydration, desludging and de-mediuming of materials. Its working principle involves the synergistic effect of mechanical vibration, screening dynamics and material characteristics. Xingaonai Heavy Industry will introduce the working principle and key technical elements of dewatering screen in detail.

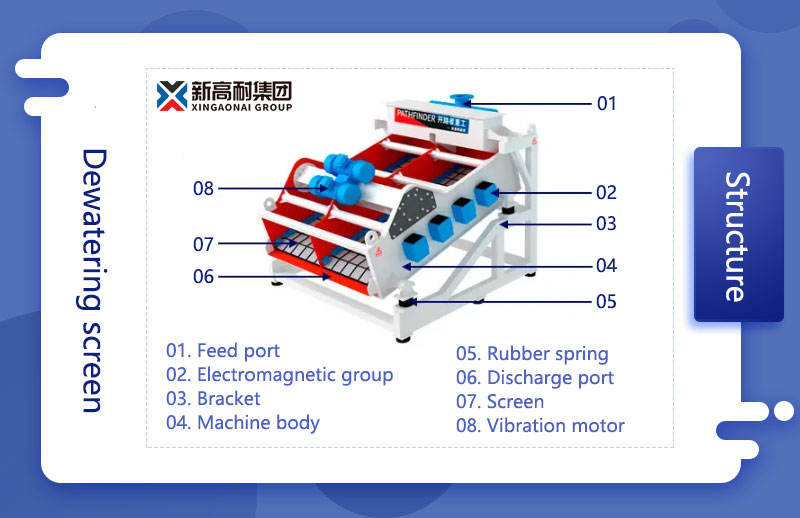

The core structure of dewatering screen usually includes screen box, exciter, vibration motor, screen, support system (spring or rubber shock absorber) and other components. Among them, the exciter is the key power source, and the dual motor self-synchronization technology is mostly used to generate centrifugal force through the eccentric block to drive the screen box to reciprocating linear motion. As a component that directly contacts the material, the screen is often made of wear-resistant and corrosion-resistant ultra-high molecular polyurethane material, or stainless steel slit screen plate to ensure efficient screening and long service life.

Material feeding and diffusion: The material enters the screen surface inside the screen box through the feed port and diffuses rapidly under the action of vibration. The high-frequency vibration of the vibration motor makes the material form a uniform thin layer on the screen surface, avoiding accumulation and promoting the separation of water and particles.

Vibration and centrifugal force: When the dual motors run synchronously in the opposite direction, the centrifugal force generated by the two sets of eccentric masses is superimposed in the vibration direction to form a single exciting force, which makes the screen box reciprocate in a specific direction. This vibration not only drives the material to move quickly on the screen surface, but also throws the water out of the gap between the particles through inertia.

Screening and grading: When the material moves on the screen surface, fine particles (meeting the size of the screen hole) fall into the lower trough through the screen, while larger particles are blocked on the screen surface and gradually move toward the discharge port. During the vibration process, the water penetrates the screen under the dual action of gravity and vibration and is discharged from the drain at the bottom of the equipment.

Dehydration stage: The screening process is usually divided into three stages: the initial dehydration stage is to initially separate the surface water by vibration; the intermediate stage (such as water spraying) removes fine mud and reduces ash content; the final dehydration stage ensures that the surface water of the particles is completely discharged through continuous vibration. Some equipment also adopts a double-layer screen design to improve processing efficiency and dehydration accuracy.

Efficient dehydration: The dehydration efficiency can reach more than 90%, and the water can be separated quickly.

Energy saving and environmental protection: Low energy consumption design reduces environmental pollution and meets the requirements of sustainable development.

Strong structure: high-strength material and optimized design, durable equipment and simple maintenance.

Customization: Parameters such as screen and amplitude can be adjusted to meet the needs of different materials and production capacity.

Convenient operation: intelligent control system, flexible parameter adjustment, and low failure rate.

Sand washing and dehydration of sand and gravel plants to improve the quality of finished sand; coal slime recovery and tailings dry discharge in coal preparation plants to reduce environmental pollution; mine tailings treatment to achieve resource reuse; solid-liquid separation process in the chemical and environmental protection fields. Its modular design and parameter adjustability enable it to flexibly respond to the dehydration needs of different materials, and can even directly replace some sand washing equipment to reduce customer costs.

The dewatering screen achieves high efficiency, stability and economy of solid-liquid separation through precise mechanical vibration and screening technology. The core of its working principle lies in the precise control of vibration force and the optimized design of screen structure. Combined with the convenience of automated debugging and maintenance, it has become an indispensable dewatering equipment in modern industry. With the continuous advancement of technology of New High-end Heavy Industry, the optimization of dewatering screen in energy saving, environmental protection, intelligent control and other aspects will further expand its application prospects and help various industries improve production efficiency and sustainable development level. If you want to know more about dewatering screen, you can consult customer service online or call +8617761642222. Xingaonai Heavy Industry will arrange senior engineers to answer your questions as soon as possible!

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap