Xingaonai

Xingaonai

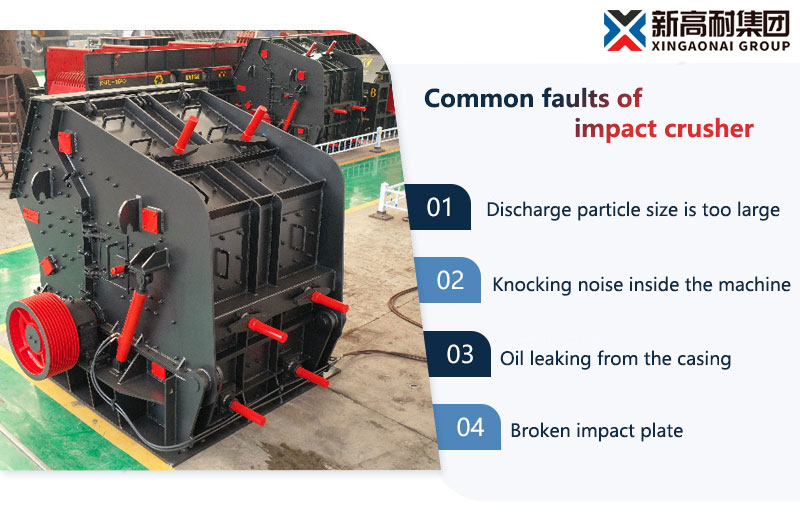

Impact crushers, as critical crushing equipment in industries such as mining, building materials, and cement, can experience various malfunctions during long-term, high-intensity operation due to wear, improper operation, or inadequate maintenance. Xingaonai Heavy Industry has summarized seven common impact crusher malfunction types and solutions to help users promptly troubleshoot problems and ensure efficient equipment operation.

Causes: Insufficient or excessive grease; contaminated or deteriorated grease; bearing damage; overtightened bearings or improperly adjusted bolts.

Solution: Check the grease level to maintain an appropriate level; clean the bearings and replace with clean grease; replace damaged bearings; and adjust the bearing gland bolts to ensure proper tightness.

Causes: Feed material is too large; uneven wear of the hammers or liner; rotor imbalance; loose foundation or untightened anchor bolts.

Solution: Check and control the feed material size to ensure it meets equipment requirements; replace severely worn hammers or liner; reinstall the blow bars and perform rotor balancing; reinforce the foundation and tighten the anchor bolts.

Cause: Belt is aged or of poor quality; pulleys are not installed in the same plane; belt tension is not appropriate.

Solution: Replace a V-belt that meets quality standards; adjust the pulley position to ensure the driving and driven pulleys are aligned; regularly check and adjust the belt tension.

Cause: Severe wear of the hammer or impact plate; excessive gap between the hammer and impact plate, typically adjusted to 15-20mm; feed particle size exceeds the equipment's handling range.

Solution: Replace or re-use the worn hammer or liner; adjust the impact plate gap to the standard range; control the feed particle size to prevent oversized materials from entering.

Cause: Uncrushable material, such as metal blocks, enters the crushing chamber; loose liner fasteners cause the plate hammers to strike the liner; broken plate hammers or other parts.

Solution: Clean foreign matter from the crushing chamber after shutting down the machine; check and tighten the liner bolts, adjust the gap between the plate hammers and the liner; replace broken plate hammers or parts. 6. Casing Oil Leakage

Causes: Deterioration or damage of seals; excessive lubricant addition or oil line blockage.

Solution: Replace damaged seals; clean the oil lines and control the lubricant addition to the appropriate level.

Causes: Fatigue damage caused by prolonged high impact loads; substandard materials or manufacturing processes.

Solution: Promptly replace the impact plate with a high-quality one; regularly inspect the impact plate and replace it if necessary.

Regular Inspections: Check bolt tightness, lubrication status, and wear of wearing parts daily before starting the machine.

Proper Operation: Strictly control feed size to avoid overloading.

Lubrication Management: Select the appropriate lubricant according to environmental conditions and replace it regularly.

Balancing Adjustment: Always perform a balancing adjustment after replacing the blow bars or rotor components.

Safety Protection: Install a belt guard to prevent accidental contact.

Systematic troubleshooting and preventive maintenance can significantly reduce the failure rate of impact crushers, extend equipment life, and improve production efficiency. Operators should develop a scientific maintenance plan based on the equipment manual and actual conditions to ensure stable operation of the equipment. If you would like to learn more about the impact crusher, please contact customer service online or call +8617761642222. Xingaonai Heavy Industry will arrange for a senior engineer to answer your questions as soon as possible!

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap