Xingaonai

Xingaonai

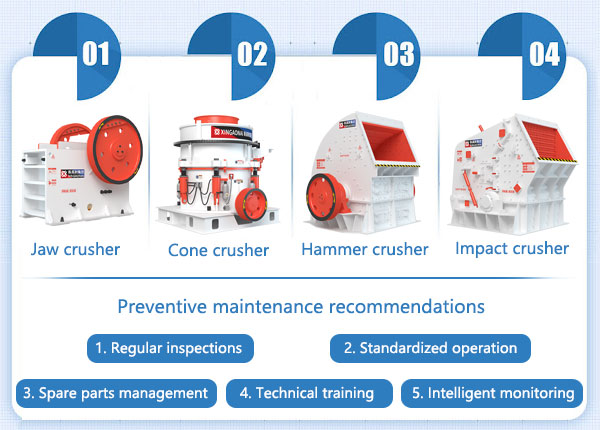

In the cement production process, crushing equipment is a key link. Commonly used crushing equipment includes: jaw crusher, Cone Crusher, hammer crusher, impact crusher, etc. The stable operation of crushing equipment directly affects production efficiency and product quality. However, due to factors such as long-term high-load operation, improper operation or equipment wear, various faults often occur in crushing equipment. Xingaonai Heavy Industry combines common fault types, causes and treatment methods to provide a reference for equipment maintenance of cement production enterprises.

1. Jaw crusher

① Fault: After a violent splitting sound, the movable jaw stops swinging, and the flywheel continues to rotate

Cause: Uncrushable materials enter the crushing chamber or the thrust plate is damaged.

Solution: Remove the pull rod spring and replace the new thrust plate.

② Fault: The crushing plate shakes and hits

Cause: The fixing bolts are loose or broken.

Solution: Tighten the bolts, replace the anti-loosening spring or broken bolts.

③ Fault: The flywheel is loose

Cause: The key or shaft end device is loose.

Solution: Tighten the key or replace the keyway, and adjust the shaft end locking device.

2. Cone Crusher

Fault: bearing overheating

Reason: oil pipe blockage, insufficient lubricating oil or bearing wear.

Solution: dredge the oil pipe, add lubricating oil, clean the bearing shell or replace the bearing.

3. Hammer crusher

Fault: blockage causes current increase

Reason: feeding too fast, high moisture content of the material or screen problem.

Solution: control the feed speed, clean the blocked pipe, replace the hammer or screen, and control the moisture content of the material below 14%.

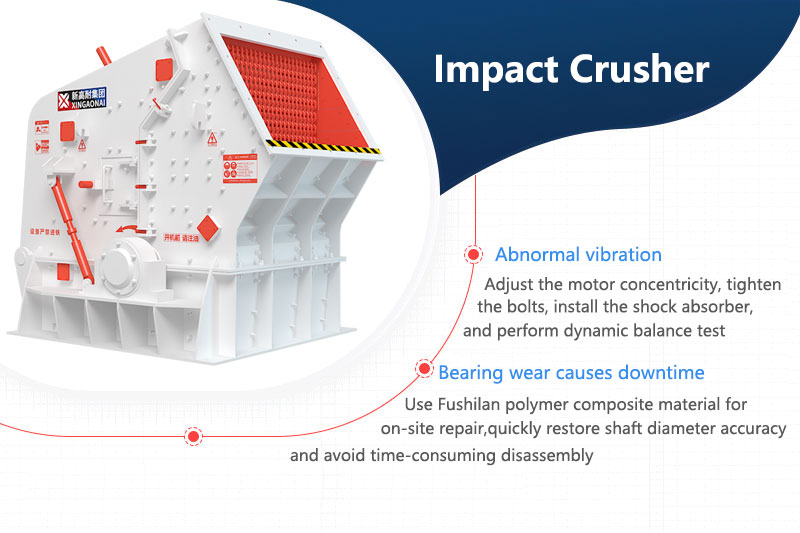

4. Impact crusher

①Fault: abnormal vibration

Reason: the motor and the equipment are not concentric, the anchor bolts are loose or the rotor is unbalanced.

Solution: adjust the concentricity of the motor, tighten the bolts, install the shock absorber, and perform a dynamic balance test.

②Fault: downtime caused by bearing wear

Solution: use Fushilan polymer composite material for on-site repair to quickly restore the shaft diameter accuracy and avoid time-consuming disassembly.

5. General fault handling principles

Blockage prevention: optimize material selection, regularly check the screen and discharge port, and install iron removal devices to prevent metal from getting stuck in the equipment.

Lubrication maintenance: regularly clean the lubrication system to ensure that the bearing oil circuit is unobstructed to avoid overheating or damage due to lack of oil.

Emergency repair: for major faults such as shaft wear and breakage, give priority to on-site rapid repair technology to reduce downtime.

To reduce the occurrence of faults, it is recommended that enterprises take the following measures:

1. Regular inspections: check equipment fasteners, lubrication systems, bearing temperature and current indicators daily;

2. Standard operation: strictly control the feed size and speed according to the equipment manual to avoid overload operation;

3. Spare parts management: reserve key wearing parts (such as hammers, bearings) and replace worn parts in time;

4. Technical training: strengthen operator training to ensure correct installation and operation of equipment;

5. Intelligent monitoring: introduce Internet of Things technologies such as vibration sensors and temperature monitoring to warn of abnormal conditions in real time.

Most of the failures of cement plant crushers are caused by wear, overload, improper maintenance and other factors. Through standardized operation, regular maintenance, timely replacement of wearing parts, and combined with new repair technology, the life of the equipment can be effectively extended, downtime losses can be reduced, and stable operation of the production line can be guaranteed. If you want to know more about "cement plant crusher failure", you can consult customer service online or call +8617761642222, and Xingaonai Heavy Industry will arrange senior engineers to answer you as soon as possible!

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap