Xingaonai

Xingaonai

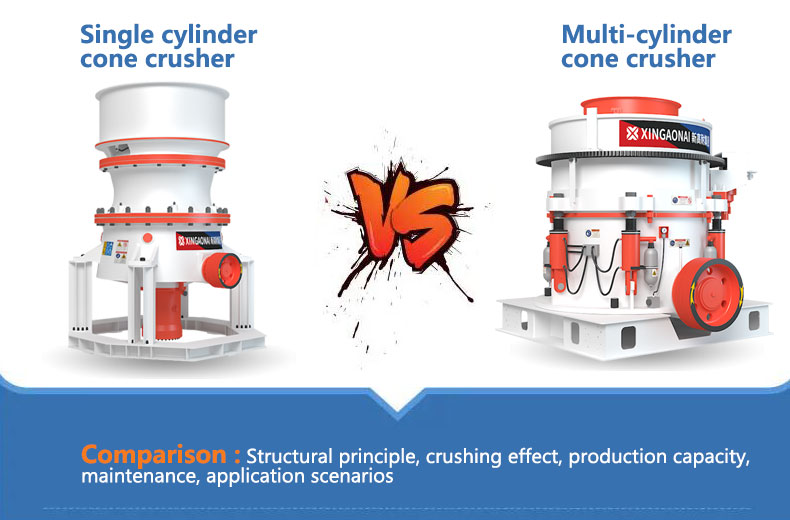

Cone crusher is a key crushing equipment in the fields of mining crushing, construction sand and gravel production, etc. Among them, single-cylinder cone crusher and multi-cylinder cone crusher are widely used in different scenarios due to their unique structure and performance characteristics. Xingaonai Heavy Industry will conduct a comprehensive comparison of the two in terms of structure, crushing effect, production capacity, maintenance, price and application scenarios to help users make reasonable choices based on actual needs.

1. Single-cylinder cone crusher

Structural composition: mainly composed of upper frame, lower frame, transmission shaft, moving cone, hydraulic cylinder, eccentric sleeve.

Working principle: The eccentric sleeve drives the moving cone to swing and extrude the material, and the bottom hydraulic cylinder realizes the discharge port adjustment and iron protection. The main shaft is supported by both ends, the force is stable, and the structure is simple and reliable.

Features: compact design, high degree of modularization, easy maintenance and installation.

2. Multi-cylinder cone crusher

Structural composition: including support sleeve, lower frame, transmission shaft, moving cone, adjustment ring, eccentric sleeve.

Working principle: The main shaft is short and thick with a large diameter. It is directly installed on the frame. The eccentric sleeve directly drives the moving cone to achieve efficient crushing through the principle of laminated crushing.

Features: The structure is complex but the bearing capacity is strong. The hydraulic system supports fully automatic adjustment and protection, and has high stability.

1. Crushing stage and particle shape

Single-cylinder cone crusher: The medium crushing effect is outstanding, the throughput is large, and it is suitable for processing medium-hardness materials. The finished product particle shape is good and there are few needle-like particles.

Multi-cylinder cone crusher: The fine crushing effect is better, the laminated crushing ability is strong, and the finished product particle shape is more uniform (mainly cubic), which is suitable for the fine crushing of high-hardness materials.

2. Production capacity

Single-cylinder cone crusher: When crushing soft ores and weathered ores, the output is higher (35%-60% higher than traditional equipment), which is suitable for large throughput scenarios.

Multi-cylinder cone crusher: It performs well when processing medium-hard and high-hard ores, with fast speed (such as some models increase by 57%). The single unit production capacity can reach 1,200 tons/hour, which is more suitable for high-intensity continuous operation.

1. Maintenance convenience

Single-cylinder cone crusher: simple structure, low failure rate, all parts can be disassembled from the top or side, few spare parts, low maintenance cost. The hydraulic system supports fast adjustment and iron protection to reduce downtime.

Multi-cylinder cone crusher: Although the structure is complex, key components (such as the fixed cone assembly) can be quickly disassembled (10 minutes), and the hydraulic system realizes automatic adjustment and overload protection, reducing the need for manual intervention.

2. Long-term cost

Single-cylinder cone crusher: stable operation, low energy consumption, long life of wearing parts, suitable for small and medium-sized production lines with limited budgets and long-term stable operation.

Multi-cylinder cone crusher: The initial investment is high, but the efficient production capacity and degree of automation can offset part of the cost, suitable for large mines or high-standard aggregate production lines.

1. Applicable scenarios for single-cylinder cone crusher

Mostly medium crushing needs, moderate material hardness (such as limestone, river pebbles).

The production line is medium-sized, and the equipment maintenance simplicity and economy are required.

Secondary crushing of stone in infrastructure projects such as construction, railways, and highways.

2. Applicable scenarios for multi-cylinder cone crushers

Fine or ultra-fine crushing requirements, processing high-hardness materials (such as granite and basalt).

Large-scale mines and machine-made sand and gravel production lines require high production capacity and high-quality finished product particles.

Scenarios with high requirements for automation and equipment stability.

Price and cost-effectiveness considerations

Single-cylinder cone crusher: The price is relatively low, suitable for projects with limited budgets, with high cost-effectiveness, taking into account efficiency and economy.

Multi-cylinder cone crusher: The price is relatively high, but considering its high-efficiency production capacity, finished product quality and automation advantages, it is more cost-effective in long-term high-load production.

The following factors should be considered when choosing a single-cylinder or multi-cylinder cone crusher: 1. Material hardness: single cylinder for soft/medium hardness, multi-cylinder for high hardness.

2. Crushing stage: single cylinder for medium crushing, multi-cylinder for fine/ultra-fine crushing.

3. Capacity requirements: multi-cylinder is preferred for large-scale and high-yield production; single cylinder can be selected for small and medium-sized production capacity.

4. Maintenance budget: If the budget is limited and the cost of maintenance is low, choose a single cylinder; for large projects, choose multiple cylinders to balance long-term benefits.

5. Automation requirements: High automation requirements give priority to multiple cylinders to simplify manual operations.

By clarifying production goals and conditions, reasonable selection can maximize equipment efficiency and reduce overall costs. If you want to know more about single-cylinder cone crushers and multi-cylinder cone crushers, you can consult online customer service or call +8617761642222. Xingaonai Heavy Industry will arrange the most professional engineers to answer your questions!

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap