Xingaonai

Xingaonai

Granite is a natural stone with high hardness, strong wear resistance and outstanding compressive resistance. It is widely used in construction, bridges, road paving and other fields. Processing it into machine-made sand can not only meet the market demand for high-quality sand and gravel aggregates, but also achieve efficient use of resources. New Gaonai Heavy Industry will introduce the core equipment and production process of granite sand making in detail to help readers fully understand this efficient and environmentally friendly production system.

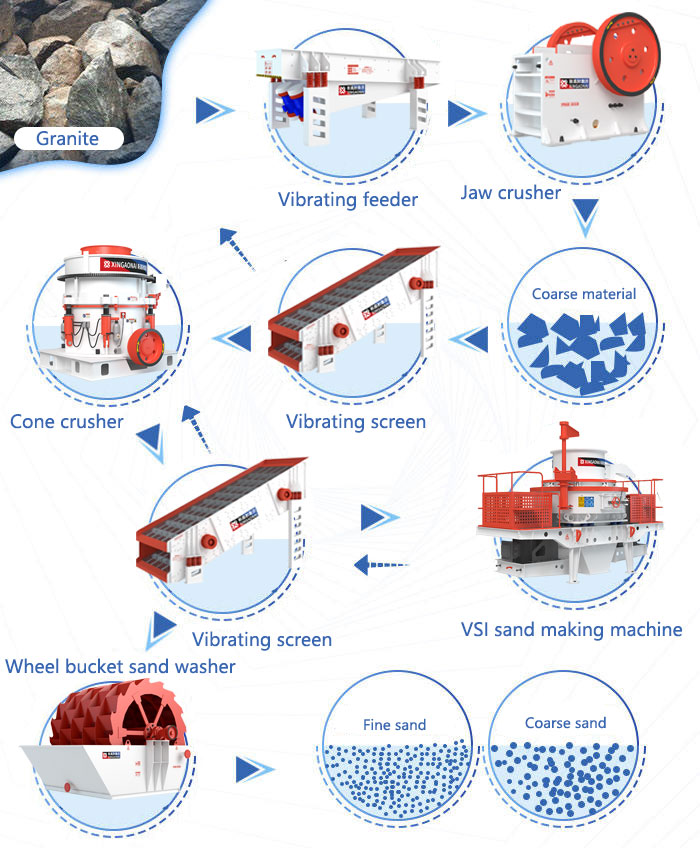

Granite sand making production lines are usually operated by multiple equipment in collaboration, and are flexibly configured according to output, raw material characteristics and finished product requirements. The core equipment includes:

1. Feeding equipment: vibrating feeder, which is responsible for feeding raw materials evenly and quantitatively into the crushing equipment to avoid blockage or excessive input.

2. Coarse crushing equipment: jaw crusher (such as PE series). Granite is hard in texture. The jaw crusher crushes large pieces of raw materials (≤500mm) into medium particle size (about 5-30cm) through the principle of extrusion crushing. It has a large crushing ratio and high efficiency, which is suitable for primary crushing.

3. Medium and fine crushing equipment: Cone crusher is suitable for medium and fine crushing of hard rock, with adjustable crushing chamber type, processing capacity of up to hundreds of tons/hour, controllable finished product particle size, and wear-resistant wearing parts.

4. Screening equipment: Vibrating screen (multi-layer screen), graded screening of crushed materials, separation of particles that meet the feed requirements of sand making machine, and return of unqualified materials to crushing equipment for reprocessing.

5. Sand making equipment: Vertical shaft impact sand making machine crushes stones into machine-made sand of ≤5mm through "stone hitting stone" or "stone hitting iron" mode, with rounded particles, meeting the requirements of high-standard construction sand.

6. Sand washing equipment: Bucket wheel sand washing machine, cleans dust and impurities on the surface of sand particles, circulates water to reduce energy consumption, and obtains clean, high-purity finished sand after dehydration.

The complete process of granite sand making can be divided into five core stages, and each link is closely connected to ensure efficient output:

1. Raw material preparation stage: Granite ore is mined from the mine and transported to the production line plant by transportation equipment for preliminary cleaning to remove surface impurities.

2. Crushing stage: Large pieces of granite enter the jaw crusher and are crushed to medium particle size (5-30cm) to reduce the load on subsequent equipment. The coarse material is sent to the cone crusher (or vertical shaft impact crusher) through a belt conveyor and further crushed to a particle size that can be handled by the sand making machine (≤40mm).

3. Screening stage: The crushed material is graded by the vibrating screen, and the particles that meet the sand making machine feeding standards enter the sand making link, and the unqualified materials return to the medium and fine crushing equipment for cyclic crushing.

4. Sand making and shaping stage: Qualified particles enter the sand making machine and are refined to ≤5mm machine-made sand through high-speed impact and friction, while removing edges and corners and optimizing the particle shape. Screening again to produce sand materials with different particle size specifications (such as 0-5mm, 5-10mm, etc.) 5. Washing and finished product processing: The sand washer cleans the sand particles, removes micro powder and soil, and improves the cleanliness. After dehydration, the sand is classified and stored, and packaged (bagged or bulk) according to customer needs or directly transported to the construction site.

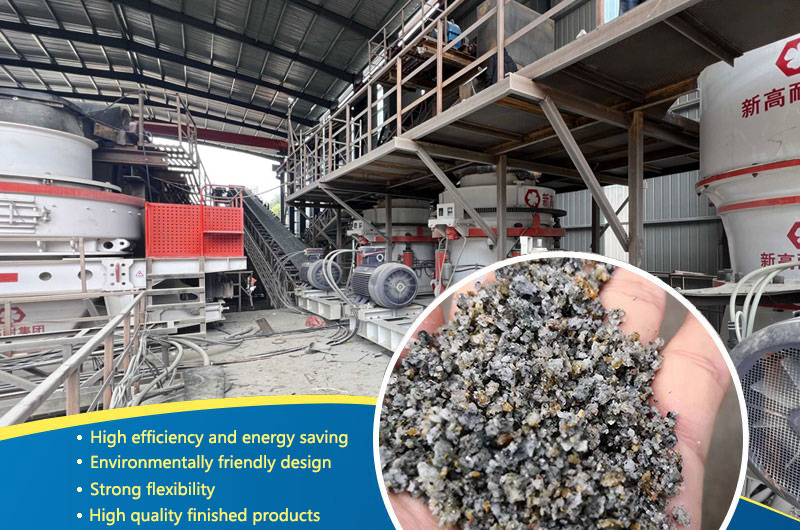

1. High efficiency and energy saving: optimized equipment combination, large crushing ratio, low energy consumption, high degree of automation, and reduced labor costs.

2. Environmental protection design: equipped with dust removal device, small dust pollution; sand washing water is recycled and meets environmental protection standards.

3. Strong flexibility: the equipment model can be adjusted according to production requirements (such as 200 tons per hour configuration), supporting two-stage, three-stage or four-stage crushing mode, and adapting to different project scales.

4. High quality of finished products: the machine-made sand particles are round and well graded, meet the national standards for construction sand, and have strong market competitiveness.

5. Compact footprint: scientific layout, reduced land occupation, suitable for various plant conditions.

The mature application of granite sand making equipment and technology provides a stable and high-quality source of sand and gravel for the construction industry. Through scientific equipment configuration and process optimization, we can not only improve production efficiency and reduce operating costs, but also achieve sustainable use of resources. With the iteration of technology, intelligent and environmentally friendly equipment will further promote the development of the sand making industry in an efficient and green direction. If you want to know more about granite sand making, you can consult customer service online or call us. We can help you design production line solutions and optimal production equipment configuration for free to meet your production needs.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap