Xingaonai

Xingaonai

Silica (mainly silicon dioxide) is an important industrial raw material, widely used in glass, ceramics, casting, construction and other fields. To process it into silica sand that meets the needs of different industries, professional sand making equipment and process flow are required. The following is a detailed introduction to the core equipment and typical process flow of silica sand making.

Silica sand making equipment usually includes key equipment for crushing, screening, sand washing, conveying and other links. The main equipment types and their functions are as follows:

1. Coarse crushing equipment: jaw crusher

Function: Process large pieces of silica (feed size ≤1200mm), and crush the raw materials to medium size (discharge size is about 220-350mm) through extrusion crushing.

Advantages: strong crushing capacity, wear resistance, large processing capacity, suitable for high hardness materials, easy installation.

2. Medium crushing equipment: cone crusher/impact crusher

Function: further crush the coarsely crushed silica (feed size ≤560mm) to produce finer particles (discharge size is about 3-60mm).

Advantages: laminated crushing reduces wear, hydraulic system facilitates cavity cleaning, and adapts to materials of different hardness.

3. Fine crushing/sand making equipment: impact sand making machine

Function: shaping and fine crushing the medium-crushed materials to the required sand particles (0-5mm), and realizing particle shaping through the principle of "stone hitting stone" or "stone hitting iron".

Advantages: uniform finished particles, cubic structure, long life of equipment wear parts, and environmentally friendly design to reduce dust.

4. Screening equipment: vibrating screen

Function: grading by particle size, separating finished sand of different specifications, ensuring that the particle size meets the standard.

5. Sand washing equipment:bucket wheel sand washing machine

Function: remove soil and impurities in sand, reduce stone powder content, and improve the purity of finished products.

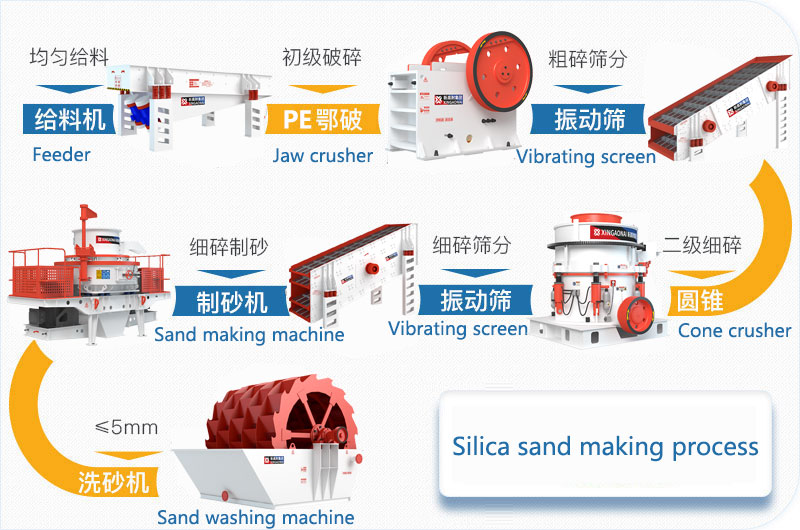

The typical silica sand making process is divided into the following stages:

1. Raw material pretreatment: large pieces of silica are sent into the raw material bin by a loader, and the vibrating feeder evenly transports them to the crushing system.

2. Primary crushing (coarse crushing): Use a jaw crusher to crush silica to 220-350mm to reduce the load of subsequent equipment.

3. Secondary crushing (medium crushing): Use a cone crusher or impact crusher to further crush to ≤55mm to meet the feeding requirements of the sand making machine.

4. Tertiary crushing/sand shaping: Use an impact sand making machine (such as a VSI sand making machine) for fine crushing and particle shaping to produce 0-5mm sand particles, while controlling the particle shape and gradation.

5. Screening and sand washing: Use a vibrating screen to screen out finished sand of different particle sizes, and then use a sand washing machine to remove surface dust and impurities to improve the purity of the sand.

6. Transportation and storage: The finished sand is transported to the storage bin by a belt conveyor or directly loaded and shipped.

1. Equipment selection basis: Select the equipment combination according to the hardness of silica, raw material particle size, finished sand specifications and output requirements.

2. Energy saving and environmental protection: Energy-saving equipment (such as roller sand making machine) is preferred, combined with dust control and noise reduction measures.

3. Flexibility design: Mobile sand making machine can be quickly deployed to adapt to on-site changes; modular design facilitates expansion of production capacity.

4. Maintenance management: Regularly replace wear-resistant parts (such as jaw plates and throwing heads), and use hydraulic systems to simplify maintenance processes.

The reasonable configuration of silica sand making equipment and process flow directly affects the quality and production cost of finished sand. By selecting efficient crushing equipment, optimizing process design, and paying attention to environmental protection and maintenance, stable and sustainable silica sand production can be achieved to meet the application needs of multiple fields.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap