Xingaonai

Xingaonai

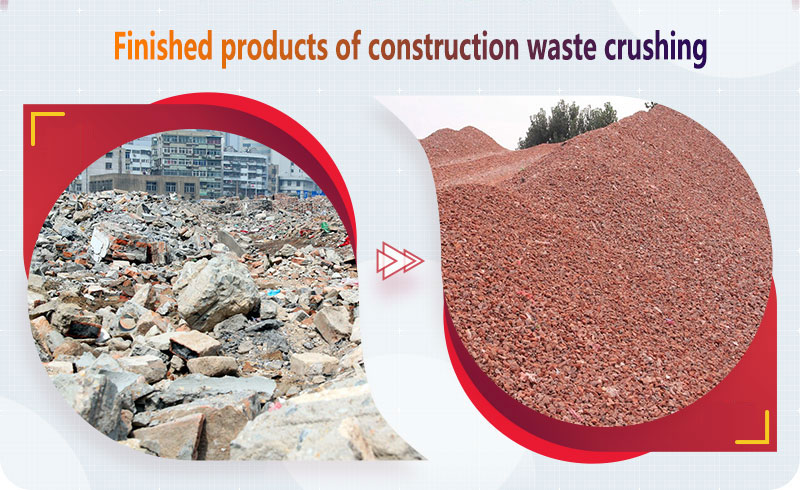

Construction waste treatment requires efficient, flexible and environmentally friendly equipment. Considering the diversity of materials (concrete, bricks, wood, metal, etc.), the following equipment types and solutions are recommended, taking into account crushing efficiency, adaptability and economy:

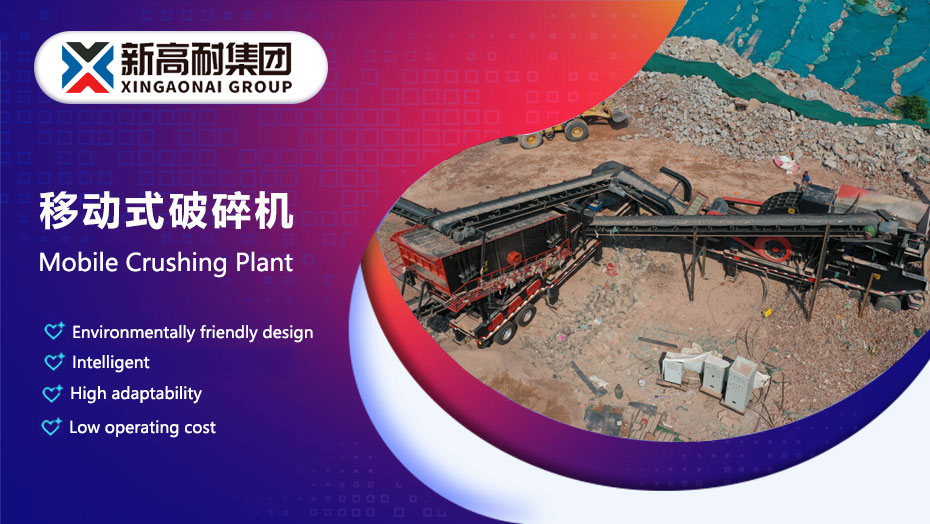

1. Mobile crushing station (preferred)

Type: crawler or tire mobile crushing station

Advantages:

①Integrated crushing, screening and conveying functions, one machine can build a factory, flexible transfer, and avoid secondary transportation pollution;

②No fixed foundation is required, fast installation and production, suitable for complex sites such as urban demolition and road construction;

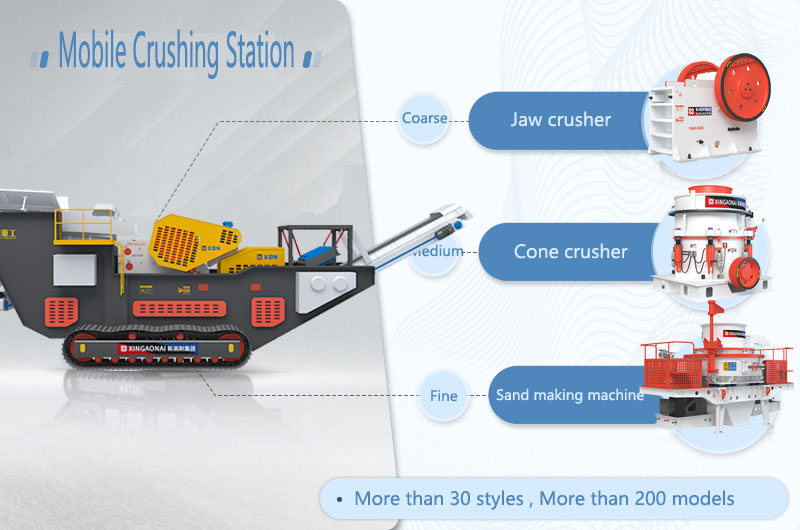

③Modular combination (such as jaw crusher + impact crusher/cone crusher), can be flexibly adjusted according to material characteristics.

2. Fixed crushing equipment (for fixed sites)

Combination solution: jaw crusher + impact crusher/cone crusher + screening machine + conveyor belt

Applicable scenarios: construction waste treatment plants with large processing capacity and fixed sites.

Equipment selection:

① Coarse crushing: jaw crusher (such as PE600×900), processing large concrete and bricks, with a large crushing ratio;

② Medium and fine crushing: impact crusher (such as PF1214) or cone crusher (such as XHP300), select according to hardness differences and optimize particle shape;

③ Screening equipment: multi-layer vibrating screen (such as 3YK2460), classify finished products, and circulate and crush unqualified materials.

Environmentally friendly design: equipped with dust removal system and noise reduction device, in line with urban environmental protection requirements;

Intelligent: hydraulic adjustment, remote monitoring, easy operation, low maintenance cost;

High adaptability: can handle garbage of different particle sizes and components, adjustable crushing ratio, flexible control of finished product particle size;

Low operating cost: mobile station reduces transportation costs, fixed line has large production capacity, and comprehensive energy consumption is optimized.

High cost-effective brand: Henan Xingaonai Heavy Industry (moderate price, durable equipment)

Since its establishment, Xingaonai Heavy Industry has been producing impact crusher equipment for decades. It has rich experience in equipment production, a large equipment production plant and advanced equipment production technology, which makes the equipment it produces cost-effective, and the strength of the manufacturer is also unmatched by other manufacturers. The company uses new processes and wear-resistant materials to manufacture equipment. There are professional personnel to supervise and guide the production process of the equipment. There will be no quality defects, and the details are handled very well, so the quality is very guaranteed.

1. Processing capacity requirements: Select the equipment model according to the daily processing capacity (such as 200 tons, 500 tons, etc.);

2. Material characteristics: If it contains more steel bars or tough materials, it is preferred to select a magnetic separation + shredder combination;

3. Site conditions: Select a tire mobile station if the space is limited, and select a crawler type if the terrain is complex;

4. Supporting equipment: If sand making is required, an impact sand making machine (VSI series) can be integrated to produce recycled aggregates.

Small mobile crushing station: about 40,000-120,000 US dollars;

Medium-sized mobile station (100-200 tons per hour): 120,000-300,000 US dollars;

Large fixed production line (500 tons per hour+): 300,000-700,000 US dollars.

Preferably choose mobile crushing station, which is fast to deploy, environmentally friendly and efficient, especially suitable for the decentralized treatment of urban construction waste; configure auxiliary equipment such as magnetic separation and screening according to the material composition (such as concrete proportion, metal content); communicate with the manufacturer to customize the plan to ensure that the equipment matches the project requirements (such as discharge particle size, production capacity target).

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap