Xingaonai

Xingaonai

The best sand making equipment needs to be customized according to actual needs, but considering the comprehensive performance, efficiency, grain shape, environmental protection and cost, impact sand making machine is generally considered to be the first choice for high-performance sand making, while mobile sand making machine is suitable for flexible and changeable scenarios. The following analyzes the best choice from different dimensions:

Advantages and applicability:

1. Excellent grain shape: Adopting the principle of "stone hitting stone/stone hitting iron", the finished sand grains are round and have few edges and corners, which meets the high standards of construction sand.

2. Efficient crushing: High crushing efficiency and large production capacity, especially suitable for medium-hard to hard materials (such as granite and basalt).

3. Intelligent and environmentally friendly: Modern models are equipped with dust removal and noise reduction systems to meet environmental protection requirements; intelligent regulation (such as frequency conversion control) improves efficiency.

4. Wear resistance and life: New equipment (such as HVI) uses wear-resistant materials, and the peripheral guard plate can be turned around to extend the life of accessories.

5. Versatility: It has both crushing and shaping functions, reduces equipment levels, and reduces investment and energy consumption.

Typical application scenarios: large-scale sand and gravel aggregate production lines, commercial mixing stations, high-speed rail/highway construction and other projects with high sand quality requirements.

1. Mobile sand making machine:

Applicable scenarios: mobile operations (such as mining in mountainous areas, construction waste treatment), projects with limited sites or requiring rapid transfer.

Advantages: integrated integration (crushing + screening + transportation), convenient transfer; intelligent control, reducing labor costs.

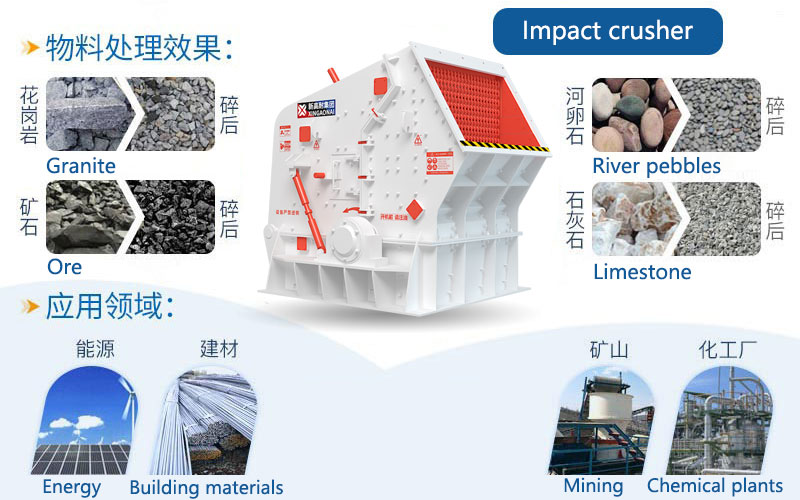

2. Impact crusher:

Applicable scenarios: medium and fine crushing and sand making of medium and low hardness materials (limestone, river pebbles).

Features: good finished product particle shape (cubic), simple equipment structure, low maintenance cost, suitable for small and medium-sized production lines with limited budgets.

3. Cone crusher + sand making machine combination:

Applicable scenarios: sand making of high hardness materials (such as granite, iron ore).

Advantages: cone crusher pretreatment improves efficiency, sand making machine shaping ensures particle shape, and the combination scheme takes into account both hardness and quality.

1. Raw material characteristics:

Hardness: For high hardness, choose cone crusher/impact crusher; for medium and low hardness, choose impact crusher or vertical shaft impact crusher.

Humidity/viscosity: For wet or sticky materials, the non-screen bottom design (such as vertical shaft type) is preferred.

2. Production capacity and budget:

Large production lines (≥100t/h) give priority to impact sand making machine or mobile sand making machine.

Small and medium-sized (≤50t/h) can choose impact crusher or roller type, which has lower cost.

3. Environmental protection and intelligent requirements:

High environmental protection area: choose equipment with dust removal and sealing system (such as HVI sand making machine).

Automation requirements: give priority to models with intelligent electronic control and remote monitoring.

4. Finished product standards:

High particle shape requirements (such as commercial concrete, high-speed rail): impact sand making machine must be selected.

Wide particle size range: combined crushing + screening equipment, or equipment with variable frequency adjustment.

High performance + high standard scenario: give priority to impact sand making machine to ensure particle shape and efficiency.

Limited budget + medium and low hardness materials: optional impact crusher, taking into account both cost and particle shape.

Complex scenario/mobile operation: mobile sand making machine is recommended to solve the problems of transfer and environmental protection in an integrated manner.

Specialized crushing of hard materials: adopt a combination of cone crusher pretreatment + sand making machine shaping.

Selection core: communicate with professional manufacturers to customize solutions based on actual raw materials, production capacity, budget and environmental protection requirements, and give priority to brand equipment with mature technology and perfect after-sales service.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap